40W FLUORESCENT INVERTER PROJECT

This 40W fluorescent inverter project is powered by 555 timer IC and used to drive fluorescent tubes, compact fluorescent lamp (CFL) and even defective fluorescent tube.

From a 12V supply voltage, timer IC generates square wave voltage of about 4.8kHz. The the primary winding (16 turns of #22 AWG) will generate current pulses of about 4A, and in return will induce a high voltage at the secondary winding (450 turns of #30 AWG) of the inverter. This voltage is enough to strike the fluorescent tube even if the filament is not heated thus very suitable to tubes with broken filaments ( burnt out filaments).

This inverter project is very suitable in lighting defective fluorescent tubes, thus helps in minimizing tubes disposal problems. The inverter also can light two 40W tubes in series.

Warning : The output of the inverter produce very high voltage and can cause electrocution. Avoid touching it

from: electronician.blogspot.com

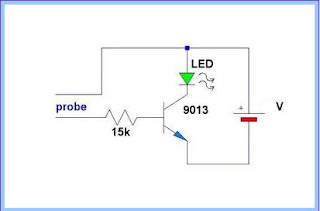

wire continuity tester by transistor

This continuity tester is very cheap, simple, and has minimal parts.The transistor is 9013 or any transistor with the same specs and the minimum voltage is about 3V. you can use this to test continuity in wires,or even diodes and resistors.

from electronician.blogspot

from electronician.blogspot

Alarm Circuit for Refrigerator Doors

The circuit will provide a beeping sound to alarm the household that the refrigerator door has been opened for more than 20 seconds.

Terminology

* 4060 – a 14-bit ripple counter with internal oscillator that has glitches which may occur in any logic gate systems connected to its outputs due to the slight delay before the later counter outputs respond to a clock pulse

* BC337 – a small signal NPN Silicon AF medium power transistor used for general purpose switching and amplifying applications with features such as TO-18 manufactured package, suited for AF driver stages and low power output stages, and divided into three group types

* Piezo Buzzer – a type of buzzer that can function as a speaker with piezoelectric disk attached where a mechanical oscillation of the piezoelectric diaphragm is damped properly to provide a wider frequency band of the sound pressure

Circuit Explanation

The appropriate location of the circuit should be near the lamp, if there is any, or near the opening. It should be enclosed in a small box so as not to expose the electronic components. The circuit’s operation depends on the detection of light by the photoresistor since the interior of the refrigerator will be dark once the door is closed. During this stage, a high resistance will be present at the photoresistor R2 at approximately greater than 200K Ohms. This value clamps the ripple counter and oscillator IC1 by making the Pin 12 at HIGH state.

The photoresistor will only lower its resistance at approximately less than 2K Ohms once the refrigerator bulb or lamp illuminates or when a ray of light strikes from the door opening. This will also cause Pin 12 to go LOW and will start IC1 to count. The piezo sounder or buzzer will beep for 20 seconds after a preset delay of 20 seconds by the time the fridge was left open. It will then stop after the same amount of time and will start the cycle over and over until the door is closed. The frequency of the beeping by the piezo sounder can be modified into 3 times per second by connecting the diode D2 to IC1 via Pin 6. The circuit may be powered by a 3 V battery source by connecting in series 2 1.5 V double A batteries.

The delay time can be cut into half by connecting the Pin 2 of IC1 to D1, and the value can be altered by adjusting the values of C1 and/or R3. To be able to operate the circuit properly, any type of photoresistor can be used. To avoid the circuit from being damaged due to excessive moisture, the circuit must not be positioned in the freezer and should be placed bear the bulb and be taken out when defrosting the refrigerator.

Application

The refrigerator door alarm circuit may be applied in old and new refrigerators as well as freezer doors, cupboards, entrance doors, and closet doors for child safety, to prevent unnecessary waste of energy causing huge electricity bills and accidental defrosts especially if they contain valuable materials that should not be thawed. Other benefits that it can provide are lowering maintenance cost, training the household to close doors, reducing coil icing, and helping maintain product integrity and prevent loss. In addition to home use, the circuit is also ideal for pharmacies, restaurants, medical facilities, hospitals, industry and institutions.

from: redcircuits.com

Portable Alarm for Personal Use

The circuit will be useful as personal alarm and anti-snatching bag unit since the design is very small and portable, which can also be used for windows and doors control.

Terminology

* BC547 – NPN small signal transistors designed for general purpose switching and amplification due to its low voltage, low current and three different gain selections

* BC327 – a PNP general purpose transistor in a TO-92 package, used for general purpose switching and amplifier applications which is suitable for AF driver stages and low power output stages of audio amplifiers due to its features of high current at 500 mA maximum and low voltage at 45 V maximum

Circuit Explanation

The setup of using this circuit is placing a small magnet close to the reed switch SW1 while being connected to the hand or clothes of the person carrying the bag with the use of a small cord. Since the circuit is small, it can be placed in a small plastic box. The magnet will loose its contact with the reed switch once the bag is snatched suddenly. The circuit will start oscillating if SW1 opens and will produce a loud alarm sound from the loudspeaker. Alternatively, the device can be placed in a pocket while the cord is connected to the bag, to form a reverse method of connection.

The high efficiency oscillator is made up by wiring a complementary transistor-pair that will drive a small 8 Ohm loudspeaker directly. A very compact assembly is the result of 3 V battery supply B1 and low count of parts used.

Any type of loudspeaker can be used but the dimension is dictated by the box where it will be placed. Since the standby current being drawn is less than 20 uA, it is not necessary to add an ON/OFF switch. A current of approximately 100 mA is consumed by the circuit when the alarm is sounding. To make the circuit more attractive, a 3.5 mm mono jack can be used as replacement for the switch while a 3.55 mm mono jack plug with its internal leads shorted can be used in place of the magnet. The tiny cord will be connected to the jack plug. The voltage used to supply this circuit should not exceed 4.5 V since the transistor Q2 might get damaged. To be on the safe side, it is recommended to use a 3 V supply with two AA cells wired in series.

Application

The personal alarms are one of the fastest growing segments in the self defense industry today because they are extremely loud and convenient to carry. It can come in the form of key chains, bright flashlights, levered hook, or wrist strap. It is used for scaring off an assailant by surprising them with high pitch alarm that may attract attention of others in the area. The opening of a window or door can provide a signaling method using this device which can be done by placing the box on the frame and the magnet on the movable part. In this way, the reed switch and the magnet will be very close when the window or door is closed.

from: redcircuits.com

light activated alarm circuit

Description.

This is the circuit diagram of a light activated switch based on National Semiconductors comparator IC LM 311 and a LDR.

The circuit is based on a voltage comparator circuit wired around IC 1.The non inverting in put of IC1 is given with a reference voltage of 6V using resistors R3 and R4. The input to the inverting input will be the voltage across the LDR that is light dependent.At darkness the resistance of the LDR will be high and so do the voltage across it.At this condition the voltage at the inverting input will be higher than the reference at non inverting pin and the out put of the comparator will be low(~o V).When the LDR is illuminated ,its resistance drops and so do the voltage across it.Now the voltage at inverting input will be lower than that at non inverting input and the out put of the comparator goes high (~12 V).This makes transistor Q1 on and it drives the relay.As a result we get a relay switching according to the intensity of the light falling on the LDR.

Notes.

* Adjust POT R1 to set the desired light intensity for switching the relay.For this illuminate the LDR with the desire intensity light.The relay will be either on or off.Adjust POT R1 slowly so that the state of the relay changes.That’s it.Now the circuit is set for the given intensity of light.

* Assemble the circuit on a good quality PCB or common board.

* You can use either a 12 V battery or a well regulated & filtered 12V DC mains operated power supply.

* The pin 5&6 (Balance & Balance/Strobe ) of IC LM311 are shorted to minimize the chance of oscillations.

* The pin out of LM311 is also given together with the circuit diagram.

from http://www.circuit-projects.com

This is the circuit diagram of a light activated switch based on National Semiconductors comparator IC LM 311 and a LDR.

The circuit is based on a voltage comparator circuit wired around IC 1.The non inverting in put of IC1 is given with a reference voltage of 6V using resistors R3 and R4. The input to the inverting input will be the voltage across the LDR that is light dependent.At darkness the resistance of the LDR will be high and so do the voltage across it.At this condition the voltage at the inverting input will be higher than the reference at non inverting pin and the out put of the comparator will be low(~o V).When the LDR is illuminated ,its resistance drops and so do the voltage across it.Now the voltage at inverting input will be lower than that at non inverting input and the out put of the comparator goes high (~12 V).This makes transistor Q1 on and it drives the relay.As a result we get a relay switching according to the intensity of the light falling on the LDR.

Notes.

* Adjust POT R1 to set the desired light intensity for switching the relay.For this illuminate the LDR with the desire intensity light.The relay will be either on or off.Adjust POT R1 slowly so that the state of the relay changes.That’s it.Now the circuit is set for the given intensity of light.

* Assemble the circuit on a good quality PCB or common board.

* You can use either a 12 V battery or a well regulated & filtered 12V DC mains operated power supply.

* The pin 5&6 (Balance & Balance/Strobe ) of IC LM311 are shorted to minimize the chance of oscillations.

* The pin out of LM311 is also given together with the circuit diagram.

from http://www.circuit-projects.com

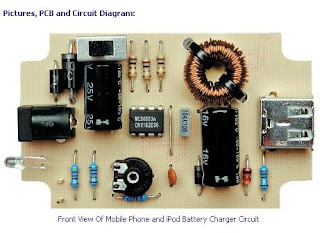

Mobile Phone and iPod Battery Charger Circuit

Charge your iPod without connecting it to a computer!

Using the USB port on your computer to charge your player’s batteries is not always practical. What if you do not have a computer available at the time or if you do not want to power up a computer just for charging? Or what if you are traveling? Chargers for Mobile Phones iPods and MP3 players are available but they are expensive and you need separate models for charging at home and in the car.

This charger can be used virtually anywhere. While we call the unit a charger, it really is nothing more than a 5V supply that has a USB outlet. The actual charging circuit is incorporated within the iPOD or MP3 player itself, which only requires a 5V supply. As well as charging, this supply can run USB-powered accessories such as reading lights, fans and chargers, particularly for mobile phones.

The supply is housed in a small plastic case with a DC input socket at one end and a USB type "A" outlet at the other end, for connecting to Mobile Phone, an iPod or MP3 player when charging. A LED shows when power is available at the USB socket. Maximum current output is 660mA, more than adequate to run any USB-powered accessory.

Parts:

P1 = 1K

R1 = 1R-0.5W

R2 = 1R-0.5W

R3 = 1R-0.5W

R4 = 1K

R5 = 560R

R6 = 10R-0.5W

R7 = 470R

C1 = 470uF-25V

C2 = 100nF-63V

C3 = 470pF

C4 = 100uF-25V

D1 = 1N5404

D2 = TVS1P6KE27A

D3 = 1N5819

D4 = 5.1V-1W Zener Diode

D5 = 5mm. Red LED

L1 = 220uH

S1 = USB 'A' Type Socket

SW1 = On/Off Switch

IC1 = MC34063A

Specifications:

Output voltage ----------------------5V

Output current ---------------------660mA maximum for 5V out

Input voltage range ------------------9.5V to 15V DC

Input current requirement ----------500mA for 9V in, 350mA for >12V input

Input current with output shorted--- 120mA at 9V in, 80mA at 15V in

Output ripple ------------------------14mV (from no load to 660mA)

Load regulation ----------------------25mV (from no load to 660mA)

Line regulation ----------------------20mV change at full load from 9 to 18V input

No load input current ----------------20mA

(The specification for the computer USB 2.0 port requires the USB port to deliver up to 500mA at an output voltage between 5.25V and 4.375V).

The circuit is based around an MC34063 switch mode regulator. This has high efficiency so that there is very little heat produced inside the box, even when delivering its maximum output current. The circuit is more complicated than if we used a 7805 3-terminal regulator but since the input voltage could be 15V DC or more, the voltage dissipation in such a regulator could be 5W or more at 500mA. and 5W is far too much for a 7805, even with quite a large heatsink. Credit for this circuit goes to SiliconChip, A wonderful electronics magazine forever

from: http://extremecircuits.blogspot.com

Li-ion Battery Charger for Mobile phone by TL431

This is a simple to build charger for single 3.7V lipo battery. The heart of the charger is TL431 shunt regulator that controls the incoming current. Charger comes with a convenient charging LED indicator. As charging current goes down so does the intensity of the LED.

from belza.cz

Mobile Phone Battery Charger Circuit

Mobile phone chargers available in the market are quite expensive. The circuit presented here comes as a low-cost alternative to charge mobile telephones/battery packs with a rating of 7.2 volts, such as Nokia 6110/6150.

Parts

R1 = 1K

R2 = 47R

R3 = 10R

R4 = 47R

C1 = 1000uF-25V

D1 = LEDs any color

D2 = LEDs any color

D3 = LEDs any color

D4 = 1N4007

D5 = 1N4007

IC1 = LM7806

T1 = 9VAC Xformer 250mA

BR1 = Diode bridge 1A

Circuit Operation:

The 220-240V AC mains supply is down-converted to 9V AC by transformer T1. The transformer output is rectified by BR1 and the positive DC supply is directly connected to the charger’s output contact, while the negative terminal is connected through current limiting resistor R2. D2 works as a power indicator with R1 serving as the current limiter and D3 indicates the charging status. During the charging period, about 3 volts drop occurs across R2, which turns on D3 through R3. An external DC supply source (for instance, from a vehicle battery) can also be used to energies the charger, where R4, after polarity protection diode D5, limits the input current to a safe value. The 3-terminal positive voltage regulator LM7806 (IC1) provides a constant voltage output of 7.8V DC since D1 connected between the common terminal (pin 2) and ground rail of IC1 raises the output voltage to 7.8V DC. D1 also serves as a power indicator for the external DC supply. After constructing the circuit on a veroboard, enclose it in a suitable cabinet. A small heat sink is recommended for IC1.

from http://extremecircuits.blogspot.com

Mobile phone charger powered by bicycle

This project is a pedal powered mobile cell phone charger.

What you'll need:

Electronic parts

1. circuit board (i.e. Radio Shack part no. 276-148)

2. bridge rectifier, 100 V, 1.4 A (i.e. Radio Shack part no. 276-1152)

3. capacitor, 1000 micro Farad, Radial-Lead Electrolytic, 35 V DC (i.e. Radio Shack part no. 272-1032)

4. voltage regulator, 7805, +5 V DC, 1 A (i.e. Radio Shack part no. 276-1770)

Tools

1. soldering iron

2. nose pliers

3. diagonal cutters

4. wire stripper

5. hookup wire

6. speaker wire

7. mounting pins

8. electrical tape

9. zip ties (optional)

Other components

1. cell phone charger

2. 12 V 6 W bicycle headlight generator

3. bicycle

Circuit diagram:

Step 2: Assemble the circuit, as shown below. Push the wires from the components through the holes in the circuit board. Use mounting pins to connect to the electronic components when necessary, and connect from pin to pin with the hookup wire.

Step 3: Solder the two cut, stripped leads from the cell phone charger to the mounting pins connected to the voltage regulator. The wire going to the center of the power jack is usually the positive/red one. Connect the wire coming from the generator to the AC terminals of the bridge rectifier. Check your work against the circuit diagram at the top of the page.

Step 4: Protect the solder side of the circuit board with a layer of electrical tape. This will help protect the circuit from shorts due to accidental contact with conductive material, and from exposure to the elements.

Step 5: You're almost ready to go. You only need to secure the wire to the frame of your bike with tape (or zip ties) and position the circuit board somewhere out of the way (we placed mine at the base of the seat post).

Step 6: Where you place the charging cell phone while you ride is up to you. I keep a basket hanging from my handlebars, so I ran the wire along the length of the center bar of the bike such that the DC plug-in ended up in the basket, where the phone stays while I'm riding. Other options are to keep the phone in a tool bag under the seat or in a saddle bag on the rear rack.

Step 7: Plug in your phone and start pedaling! The phone should react just as if it were charging from a wall outlet.

How it works:

When engaged, the generator wheel rolls against the bike tire. The motion produces electricity, and the greater your speed, the greater the voltage output. The cord from the generator leads first to the circuit board's bridge rectifier, which converts the AC to DC. In other words, the up-and-down, positive-to-negative current becomes a steady positive current. Then, the capacitor levels out the DC voltage, producing a steady voltage inflow to the voltage regulator. The voltage regulator is crucial, as the phone only needs five volts to charge, whereas fast pedaling can produce 30 volts or more, which is enough to fry the average cell phone. The regulator controls the voltage, putting a five-volt ceiling on the power entering the phone.

Results:

Starting with a dead cell phone, plugged in and placed in my basket, I spent approximately three hours and 25 miles riding in the streets of San Francisco to charge it back to full power. Much to my surprise, an easy speed of only four miles per hour was enough to keep the power production at the necessary five volts, and almost as soon as I rolled out the door, the phone lit up and beeped, indicating that it had begun to charge. Even in stop-and-go city cycling, my speed rarely dropped below charging speed, allowing the battery to juice up almost continuously.

The generator made riding significantly more difficult due to the friction of the roller against the tire, so you might want to disengage the generator on hard uphill climbs. Also, a lot of potential energy is wasted on long downhill runs, since voltage over and above 5V is lost as heat from the regulator. The system could be improved by installing a battery to catch and store the overflow energy for use when the output voltage drops below 5V, as when the bike is moving slowly or at rest.

from www.srimeenakshimobiles.com

AA Battery Solar Charger

Introduction:

This almost trivial circuit may be used to charge a pair of AA or AAA sized rechargeable battery cells from sunlight. The circuit has been used to keep a Palm Pilot and walkman radio running perpetually. This is an unregulated charger, proper charging is achieved by placing the unit in the sun for a known amount of time, this time varies according to the battery type.

Specifications

Open Circuit Voltage: about 4.0V

Closed Circuit Current: about 25ma (depending on the solar cell types)

Charge Current: < 25ma (depending on the solar cell types)

Charge Time AA cells: approximately 1 full day of direct sunlight

Charge Time AAA cells: approximately 1/2 full day of sunlight

Theory

Each of the solar cells develops about 0.5 volts across itself when in full sunlight. The string of 8 solar cells puts out around 4V with no load. When the solar cells are connected to a battery, a current will flow and the battery will charge.

Two versions of the circuit are shown in the schematic, the 8 solar cell panel with a diode is the recommended circuit. The diode prevents the battery from discharging through the cells at night and the 8th cell boosts the voltage up enough to compensate for the voltage drop across the diode. For an 8 solar cell panel, connect jumper J2 and disconnect J1. For a 7 solar cell panel, connect jumper J1 and eliminate SC8 and D1. Typically, the jumpers are not necessary, they are shown in the schematic to illustrate two ways to to build the circuit.

For operation in cloudy weather, it may be useful to add one or two additional solar cells. It is a good idea to temporarily insert an amp (microamp) meter in series with the battery to measure the charging current in various light conditions.

Since solar cells are current-limited devices, it is possible to use the circuit as-is to charge a single battery cell. If one cell is all you ever need to charge, five solar cells and a series diode will be sufficient for the task.

Construction

Lay out the solar cells to determine the size of the circuit board, allow for about 1/4" (1cm) of extra space around all four sides. Cut out one piece of perforated circuit board, one piece of solid PC board, and one piece of 1/8" clear plexiglass in this dimension. File all 3 pieces to achieve smooth edges.

Drill 2 holes down the center line of the 3 pieces while holding them together allowing room for the screws to pass between the solar cells. Mount the two battery holders on the blank piece of circuit board with screws or silicon rubber glue. If the solar cells don't have wire connections, solder thin wires to the cells. Wire-wrap wire works well for this. Be careful not to overheat the solar cells, use a small soldering iron and only touch the cells for a few seconds at a time. The solar cells should be secured to the perf board with a drop of silicon rubber on the back side, or they can be held in place with the wires of the solar cell if you have the right kind of cell. Wire all of the cells in series, plus to minus, connect the two end wires to longer wires that go to the diode and battery holder. Typically, the positive connection is the metal on the back of the solar cell and the negative connection is the wire grid on the blue (front) side.

Using a pair of 3/4 inch 6-32 machine screws and nuts or washers, make a sandwich of the 3 boards. Use the nuts or washers to make gaps between the board layers, it is important to prevent any contact between the solar cells and the plexiglass. The solar cells are very brittle and will break under compression.

If you want to make the panel waterproof, cut 4 thin strips of solid circuit board or other plastic to fit around the sides of the sandwich. Glue these boards to the sides of the assembly with silicon rubber. Apply a small drop of glue to where the screws go through the plexiglass.

Alignment

None required unless you count pointing the panel at the sun.

Use

Insert two rechargeable cells in the battery holders, point the device at the sun, and let batteries charge for a few hours. Larger cells will need more charging time. The solar array should be placed in direct sun, it should not be shaded in any way. It might be a good idea to monitor the battery voltage during the first few charge cycles to get an idea of how much time is needed to reach a full charge.

Do not let the rechargeable cells overheat. If the charger is left outdoors in the summer, the excess heat can cause the cells to leak out their electrolyte goo, ruining the cells. Operating the charger indoors behind a window may help to reduce the heat. Operation behind a window will also cause a drop in the charge current, resulting in a longer charge time.

This circuit works with rechargeable alkaline cells, NICD cells, or any other rechargeable that has a potential of 1.5V or lower per cell. If you build the 7 cell version (no diode), remove the cells at night to prevent discharge through the solar cells.

It is advisable to connect a volt meter across the battery with a pair of alligator clips to observe the battery voltage as it charges. If you have a lot of batteries to charge, it is best to charge cells that are matched by brand. If possible, use cell pairs that start with a similar voltage, this allows both cells to finish charging at the same time.

The NiCd Memory Effect

Keep in mind that the so-called NiCd "memory effect" is largely an urban legend that started from a legitimate early 1960s Nasa experiment involving first generation NiCd cells charged and discharged within a very tight voltage range. The two biggest killers of modern NiCd cells are overheating during charging, and reverse voltages applied to the weak cells as the result of the complete discharge of multi-cell NiCd packs.

Overheating of NiCD cells can cause the loss of electrolyte, resulting in lowered cell capacity. The NiCd cells in cheaper appliances such as cordless phones and portable vacuum cleaners will last much longer if they are removed from the charger as soon as they become warm. Leaving a NiCD pack in a charger 24 hours a day will result in short battery life.

Reverse voltage can cause conductive dendrites to grow in the cells making them self-discharge more rapidly. So called "memory effect" battery dischargers can actually cause the reverse voltage problem if used on multiple cell packs. The weakest cell in a pack will go to zero volts, then negative volts as the stronger cells discharge. Discharging can be a good way to insure that all cells are charged from the same starting point, just be sure to limit the minimum discharge voltage to around 1V per cell. The BatteryUniversity.com has a good article on the behavior of aging NiCD cells, and tips on cell restoration.

Parts

SC1-SC8 single photovoltaic solar cell, .5V, 20 to 50 ma output each in full sun

D1 1x 1N5818 Schottky Diode

Battery Holder 1x 2 cell AA or AAA battery holder

Battery 2x AA or AAA NiCD or NiMH rechargeable cells

Perf Board 1x for mounting solar cells

PC board 1x solid piece for mounting battery holder

Plexiglass 1x approx. 1/8" thick, cut to size

misc hardware, wire

from http://www.solorb.com

This almost trivial circuit may be used to charge a pair of AA or AAA sized rechargeable battery cells from sunlight. The circuit has been used to keep a Palm Pilot and walkman radio running perpetually. This is an unregulated charger, proper charging is achieved by placing the unit in the sun for a known amount of time, this time varies according to the battery type.

Specifications

Open Circuit Voltage: about 4.0V

Closed Circuit Current: about 25ma (depending on the solar cell types)

Charge Current: < 25ma (depending on the solar cell types)

Charge Time AA cells: approximately 1 full day of direct sunlight

Charge Time AAA cells: approximately 1/2 full day of sunlight

Theory

Each of the solar cells develops about 0.5 volts across itself when in full sunlight. The string of 8 solar cells puts out around 4V with no load. When the solar cells are connected to a battery, a current will flow and the battery will charge.

Two versions of the circuit are shown in the schematic, the 8 solar cell panel with a diode is the recommended circuit. The diode prevents the battery from discharging through the cells at night and the 8th cell boosts the voltage up enough to compensate for the voltage drop across the diode. For an 8 solar cell panel, connect jumper J2 and disconnect J1. For a 7 solar cell panel, connect jumper J1 and eliminate SC8 and D1. Typically, the jumpers are not necessary, they are shown in the schematic to illustrate two ways to to build the circuit.

For operation in cloudy weather, it may be useful to add one or two additional solar cells. It is a good idea to temporarily insert an amp (microamp) meter in series with the battery to measure the charging current in various light conditions.

Since solar cells are current-limited devices, it is possible to use the circuit as-is to charge a single battery cell. If one cell is all you ever need to charge, five solar cells and a series diode will be sufficient for the task.

Construction

Lay out the solar cells to determine the size of the circuit board, allow for about 1/4" (1cm) of extra space around all four sides. Cut out one piece of perforated circuit board, one piece of solid PC board, and one piece of 1/8" clear plexiglass in this dimension. File all 3 pieces to achieve smooth edges.

Drill 2 holes down the center line of the 3 pieces while holding them together allowing room for the screws to pass between the solar cells. Mount the two battery holders on the blank piece of circuit board with screws or silicon rubber glue. If the solar cells don't have wire connections, solder thin wires to the cells. Wire-wrap wire works well for this. Be careful not to overheat the solar cells, use a small soldering iron and only touch the cells for a few seconds at a time. The solar cells should be secured to the perf board with a drop of silicon rubber on the back side, or they can be held in place with the wires of the solar cell if you have the right kind of cell. Wire all of the cells in series, plus to minus, connect the two end wires to longer wires that go to the diode and battery holder. Typically, the positive connection is the metal on the back of the solar cell and the negative connection is the wire grid on the blue (front) side.

Using a pair of 3/4 inch 6-32 machine screws and nuts or washers, make a sandwich of the 3 boards. Use the nuts or washers to make gaps between the board layers, it is important to prevent any contact between the solar cells and the plexiglass. The solar cells are very brittle and will break under compression.

If you want to make the panel waterproof, cut 4 thin strips of solid circuit board or other plastic to fit around the sides of the sandwich. Glue these boards to the sides of the assembly with silicon rubber. Apply a small drop of glue to where the screws go through the plexiglass.

Alignment

None required unless you count pointing the panel at the sun.

Use

Insert two rechargeable cells in the battery holders, point the device at the sun, and let batteries charge for a few hours. Larger cells will need more charging time. The solar array should be placed in direct sun, it should not be shaded in any way. It might be a good idea to monitor the battery voltage during the first few charge cycles to get an idea of how much time is needed to reach a full charge.

Do not let the rechargeable cells overheat. If the charger is left outdoors in the summer, the excess heat can cause the cells to leak out their electrolyte goo, ruining the cells. Operating the charger indoors behind a window may help to reduce the heat. Operation behind a window will also cause a drop in the charge current, resulting in a longer charge time.

This circuit works with rechargeable alkaline cells, NICD cells, or any other rechargeable that has a potential of 1.5V or lower per cell. If you build the 7 cell version (no diode), remove the cells at night to prevent discharge through the solar cells.

It is advisable to connect a volt meter across the battery with a pair of alligator clips to observe the battery voltage as it charges. If you have a lot of batteries to charge, it is best to charge cells that are matched by brand. If possible, use cell pairs that start with a similar voltage, this allows both cells to finish charging at the same time.

The NiCd Memory Effect

Keep in mind that the so-called NiCd "memory effect" is largely an urban legend that started from a legitimate early 1960s Nasa experiment involving first generation NiCd cells charged and discharged within a very tight voltage range. The two biggest killers of modern NiCd cells are overheating during charging, and reverse voltages applied to the weak cells as the result of the complete discharge of multi-cell NiCd packs.

Overheating of NiCD cells can cause the loss of electrolyte, resulting in lowered cell capacity. The NiCd cells in cheaper appliances such as cordless phones and portable vacuum cleaners will last much longer if they are removed from the charger as soon as they become warm. Leaving a NiCD pack in a charger 24 hours a day will result in short battery life.

Reverse voltage can cause conductive dendrites to grow in the cells making them self-discharge more rapidly. So called "memory effect" battery dischargers can actually cause the reverse voltage problem if used on multiple cell packs. The weakest cell in a pack will go to zero volts, then negative volts as the stronger cells discharge. Discharging can be a good way to insure that all cells are charged from the same starting point, just be sure to limit the minimum discharge voltage to around 1V per cell. The BatteryUniversity.com has a good article on the behavior of aging NiCD cells, and tips on cell restoration.

Parts

SC1-SC8 single photovoltaic solar cell, .5V, 20 to 50 ma output each in full sun

D1 1x 1N5818 Schottky Diode

Battery Holder 1x 2 cell AA or AAA battery holder

Battery 2x AA or AAA NiCD or NiMH rechargeable cells

Perf Board 1x for mounting solar cells

PC board 1x solid piece for mounting battery holder

Plexiglass 1x approx. 1/8" thick, cut to size

misc hardware, wire

from http://www.solorb.com

solar cell phone charger circuit

This little gadget uses a small 3 volt solar cell to charge a 6 volt NiCad battery pack which, in turn, may be used to charge many models of cell phones and other portable devices. The circuit "scavenges" energy from the solar cell by keeping it loaded near 1.5 volts (maximum energy transfer value) and trickle charges the internal battery pack with current pulses. The simple circuit isn't the most efficient possible but it manages a respectable 70% at 100 mA from the cell and 30% when the cell is providing only 25 mA which is actually pretty good without going to a lot more trouble or using more exotic components.

Ref. Description

PC1 3 volt solar cell from a sidewalk solar light

C1 22 uF, 10 volt (values not critical)

C2 100 pF, any voltage or type, typically ceramic

C3 10 uF, 16 volt or more for higher voltage battery

R1 1.5 k, any type

R2 3.9k, any type

R3 10k, any type

R4 180 ohm, any type

R5 4.7k, any type

R6 10 ohm PTC (see text).

L1 50 to 300 uH (see text)

D1 1N5818 schottky rectifier, just about any will do.

Q1 2N4403, or similar

Q2 2N4401, or similar

J1 output jack

B1 6 volt NiCad battery w/fuse

Here is how it works:

When the voltage on the emitter of Q1 rises a little over 1.5 volts, both transistors turn on quickly, snapping on due to the positive feedback through R5 and C2. The current increases in L1 through Q2 until the voltage across the cell drops somewhat below 1.5 volts. The circuit then switches off quickly and the voltage on the collector of Q2 jumps up, turning on D1, allowing the inductor current to flow into the battery. Once the inductor has discharged into the battery, the process starts over. The circuit can charge higher voltage batteries without any circuit changes since the voltage will jump up quite high on the collector when the transistors turn off. The circuit should not be operated without a battery attached. For a little more efficiency, increase R5 in proportion to the voltage increase on the battery. (For example, double R5 for charging a 12 volt battery.) A NiCad battery was chosen because they are particularly forgiving of overcharging, simply converting the excess current into heat.

The photocell was salvaged from an inexpensive solar sidewalk illuminator and it has an open-circuit voltage of about 3 volts and supplies about 100 mA in bright sunlight. The circuit can handle more current but avoid cells that supply more than 250 mA. The inductor should have a low resistance winding but a surprising number of cores will work fairly well. The core in the prototype is actually a piece of ferrite antenna rod chosen simply to fit in the extremely limited confines of the package. Another unlikely inductor that worked well was 10 turns on one of those 1" long, 1/2" diameter large ferrite beads often used for power line baluns! The value of inductance isn't critical, perhaps between 40 and 300 uH and during proper operation there will be a pulse waveform on the collector of Q2 with several 10s of microseconds period. This prototype operates at about 40 uS as shown and the inductance measures about 50 uH.

For experimenting with cores or other circuit values, replace the NiCad battery with a zener of the same voltage and replace the solar cell with a 3 volt power supply with a series resistor, about 22 ohms to simulate moderate sun. Measure the current in the zener and compare that power (zener current times zener voltage) to the power coming from the power supply (3 volts times power supply current) to see how the circuit is doing. When the power in the zener is over half the power from the supply, the inductor is good enough.

It is mandatory that a fuse be added near one of the terminals of the battery! (See the little green 2 amp fuse along the bottom edge of the battery.) Battery packs can supply dangerous current levels! Keep the lead from the fuse to the battery terminal as short as practical. I had to change this fuse; I'm glad it was there!

In addition to the fuse a 10 ohm PTC was added in series with the output to limit the available power but also to allow the unit to charge my Nokia phone which doesn't like a very low impedance battery as a charging source. (The phone simply displays "battery not charging".) I have a few thousand of those, if you need a couple (charles@wenzel.com). The PTC is actually soldered directly to the copper board and one end of the fuse connects directly to the top side.

Don't copy my assembly technique! First of all, I had to cut all the mounting posts out of the case to get the battery to fit and it is held in by glue. Notice the silver nuts soldered onto the PCB for securing the cover! Secondly, there is very little height for the circuitry so everything is pressed down flat against a piece of copper clad board using little bits of board for the connections. That's a fine technique but this prototype was just too tight for comfort. Third, I had to search a while to find an inductor that would fit! All the room was used up before I got to one of the larger parts! Having said all this, the final unit is very compact and solid but there was too much luck involved!

It works great! I simply leave it on my dash until I need it. I've charged several Nokia phones without a problem. It is actually more convenient than a cigarette lighter adapter because it can travel with the phone and it doesn't need sunlight to charge the phone. I will say that the thing charges my phone suspiciously fast and I wonder if I should increase the output resistance. Fast charging cell phone batteries shortens their life, if I understand correctly. Most phones have sophisticated internal charging circuits but I suspect the manufacturers sacrifice battery life for fast charging. It might simply be that my phone hasn't been significantly discharged since I built the charger.

from: http://www.techlib.com

Ref. Description

PC1 3 volt solar cell from a sidewalk solar light

C1 22 uF, 10 volt (values not critical)

C2 100 pF, any voltage or type, typically ceramic

C3 10 uF, 16 volt or more for higher voltage battery

R1 1.5 k, any type

R2 3.9k, any type

R3 10k, any type

R4 180 ohm, any type

R5 4.7k, any type

R6 10 ohm PTC (see text).

L1 50 to 300 uH (see text)

D1 1N5818 schottky rectifier, just about any will do.

Q1 2N4403, or similar

Q2 2N4401, or similar

J1 output jack

B1 6 volt NiCad battery w/fuse

Here is how it works:

When the voltage on the emitter of Q1 rises a little over 1.5 volts, both transistors turn on quickly, snapping on due to the positive feedback through R5 and C2. The current increases in L1 through Q2 until the voltage across the cell drops somewhat below 1.5 volts. The circuit then switches off quickly and the voltage on the collector of Q2 jumps up, turning on D1, allowing the inductor current to flow into the battery. Once the inductor has discharged into the battery, the process starts over. The circuit can charge higher voltage batteries without any circuit changes since the voltage will jump up quite high on the collector when the transistors turn off. The circuit should not be operated without a battery attached. For a little more efficiency, increase R5 in proportion to the voltage increase on the battery. (For example, double R5 for charging a 12 volt battery.) A NiCad battery was chosen because they are particularly forgiving of overcharging, simply converting the excess current into heat.

The photocell was salvaged from an inexpensive solar sidewalk illuminator and it has an open-circuit voltage of about 3 volts and supplies about 100 mA in bright sunlight. The circuit can handle more current but avoid cells that supply more than 250 mA. The inductor should have a low resistance winding but a surprising number of cores will work fairly well. The core in the prototype is actually a piece of ferrite antenna rod chosen simply to fit in the extremely limited confines of the package. Another unlikely inductor that worked well was 10 turns on one of those 1" long, 1/2" diameter large ferrite beads often used for power line baluns! The value of inductance isn't critical, perhaps between 40 and 300 uH and during proper operation there will be a pulse waveform on the collector of Q2 with several 10s of microseconds period. This prototype operates at about 40 uS as shown and the inductance measures about 50 uH.

For experimenting with cores or other circuit values, replace the NiCad battery with a zener of the same voltage and replace the solar cell with a 3 volt power supply with a series resistor, about 22 ohms to simulate moderate sun. Measure the current in the zener and compare that power (zener current times zener voltage) to the power coming from the power supply (3 volts times power supply current) to see how the circuit is doing. When the power in the zener is over half the power from the supply, the inductor is good enough.

It is mandatory that a fuse be added near one of the terminals of the battery! (See the little green 2 amp fuse along the bottom edge of the battery.) Battery packs can supply dangerous current levels! Keep the lead from the fuse to the battery terminal as short as practical. I had to change this fuse; I'm glad it was there!

In addition to the fuse a 10 ohm PTC was added in series with the output to limit the available power but also to allow the unit to charge my Nokia phone which doesn't like a very low impedance battery as a charging source. (The phone simply displays "battery not charging".) I have a few thousand of those, if you need a couple (charles@wenzel.com). The PTC is actually soldered directly to the copper board and one end of the fuse connects directly to the top side.

Don't copy my assembly technique! First of all, I had to cut all the mounting posts out of the case to get the battery to fit and it is held in by glue. Notice the silver nuts soldered onto the PCB for securing the cover! Secondly, there is very little height for the circuitry so everything is pressed down flat against a piece of copper clad board using little bits of board for the connections. That's a fine technique but this prototype was just too tight for comfort. Third, I had to search a while to find an inductor that would fit! All the room was used up before I got to one of the larger parts! Having said all this, the final unit is very compact and solid but there was too much luck involved!

It works great! I simply leave it on my dash until I need it. I've charged several Nokia phones without a problem. It is actually more convenient than a cigarette lighter adapter because it can travel with the phone and it doesn't need sunlight to charge the phone. I will say that the thing charges my phone suspiciously fast and I wonder if I should increase the output resistance. Fast charging cell phone batteries shortens their life, if I understand correctly. Most phones have sophisticated internal charging circuits but I suspect the manufacturers sacrifice battery life for fast charging. It might simply be that my phone hasn't been significantly discharged since I built the charger.

from: http://www.techlib.com

Subscribe to:

Comments (Atom)